British company that worked with Elon Musk sends tiny factory capable of reaching 1,000C into space

Cardiff-based Space Forge worked with SpaceX to launch the compact orbital factory

Don't Miss

Most Read

A Welsh aerospace firm has deployed a miniature manufacturing facility into Earth's orbit.

Space Forge, headquartered in Cardiff, has demonstrated that its compact orbital factory can operate its furnace at extreme heat levels, often as high as 1,000C.

The achievement marks a major step forward in the emerging field of space-based manufacturing.

The company's facility, roughly the size of a household microwave, is now functioning several hundred kilometres above Earth.

TRENDING

Stories

Videos

Your Say

Now, scientists have demonstrated that its furnace can be switched on and reach temperatures of around 1,000C.

They plan to manufacture material for semiconductors, which can be used back on Earth in electronics in communications infrastructure, computing and transport.

Conditions in space are ideal for making semiconductors, which have the atoms they're made of arranged in a highly ordered 3D structure.

Manufacturing in the weightless conditions of space offers potential advantages that cannot be replicated on Earth, where gravity imposes fundamental limitations on certain production processes.

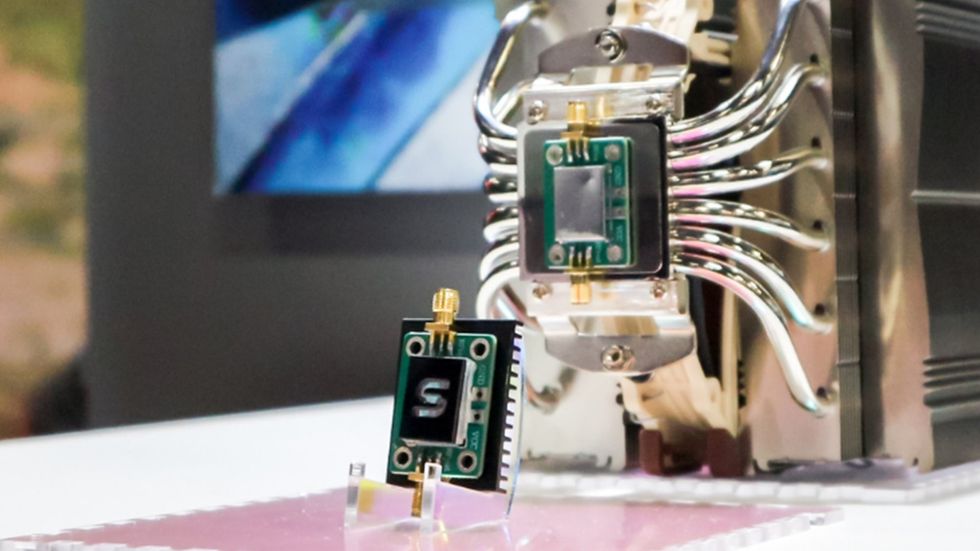

The factory on board the SpaceX flight

|SPACE FORGE

CEO of Space Forge Josh Western told the BBC: "The work that we're doing now is allowing us to create semiconductors up to 4,000 times purer in space than we can currently make here today.

"This sort of semiconductor would go on to be in the 5G tower in which you get your mobile phone signal.

"It's going to be in the car charger you plug an EV into, it's going to be in the latest planes."

The transport industry, increasingly reliant on advanced electronic systems, may also find applications for materials produced in orbit.

LATEST DEVELOPMENTS FROM SPACE

Conditions in space are ideal for making conductors

|SPACE FORGE

Head of Space at the Science Museum Libby Jackson said: "In-space manufacturing is something that is happening now.

"It's the early days and they're still showing this in small numbers at the moment.

"But by proving the technology it really opens the door for an economically viable product, where things can be made in space and return to Earth and have use and benefit to everybody on Earth.

"That's really exciting."

The company's mini-factory launched on a SpaceX rocket, which the team has been testing using systems from their mission control in Cardiff.

Space Forge's Payload Operations Lead Veronica Viera said seeing an image from inside the furnace was "one of the most exciting moments of my life".

Ms Viera added: "This is so important because it's one of the core ingredients that we need for our in-space manufacturing process.

"So being able to demonstrate this is amazing."

The team working on the Pridwen shield

|SPACE FORGE

Now, the team are to build a bigger space factory, one which would be able to make semiconductor material for 10,000 chips.

The group are also working on a heat shield called Pridwen.

Named after King Arthur's shield, will be deployed to protect the spacecraft from the intense temperatures it will experience as it re-enters the Earth's atmosphere.

Our Standards: The GB News Editorial Charter