UK car production 'cannot afford to wait' as Labour faces pressure to help crucial industry

WATCH: Stellantis announces the closure of Vauxhall's Luton factory with 1,100 jobs at risk

|GB NEWS

Last year, the automotive industry contributed £92billion turnover and £25billion value added to the UK economy

Don't Miss

Most Read

Latest

British manufacturers continue to urge the Government to intervene and slash energy costs for factories as the UK hits a major milestone.

The automotive sector has achieved a milestone in renewable energy generation, producing 60.3 gigawatt-hours of clean electricity last year through solar panels and wind turbines at manufacturing facilities.

The figure represents a 30.3 per cent surge compared to the previous year, according to the Society of Motor Manufacturers and Traders' latest sustainability report published today.

The renewable electricity generated at car and commercial vehicle plants helped prevent nearly 12,500 tonnes of CO2 emissions.

Do you have a story you'd like to share? Get in touch by emailing motoring@gbnews.uk

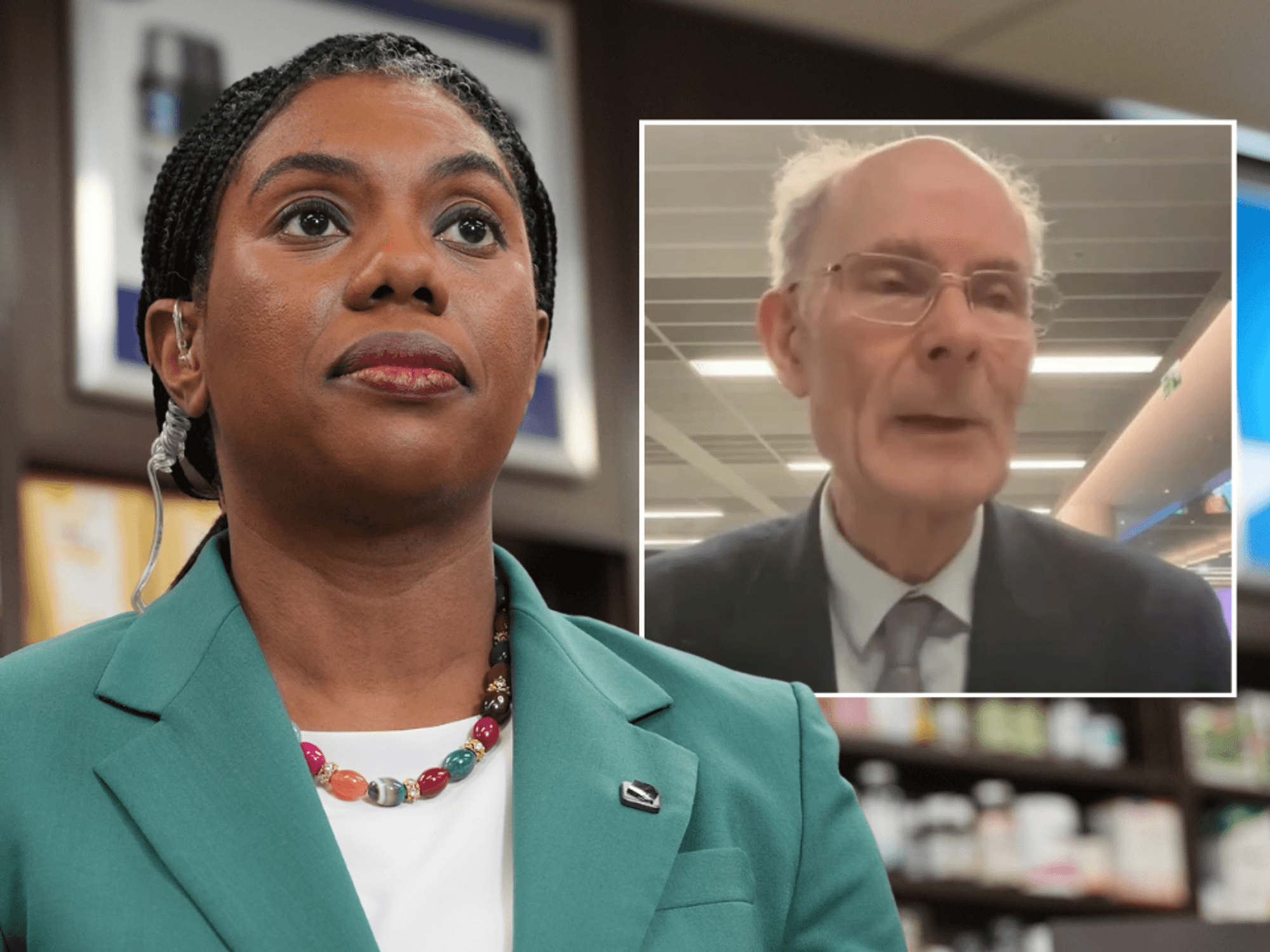

Experts have called on the Government to cut electricity prices to support the automotive industry

|PA

The achievement comes as manufacturers continue investing in more efficient production processes, reducing energy consumption per vehicle by 2.4 per cent despite declining production volumes.

Electrified models now account for more than a third of UK car production, with these vehicles requiring more energy to manufacture than conventional alternatives.

Despite these achievements, the industry faces severe infrastructure constraints that could derail its green ambitions.

Grid connection delivery timelines currently average nearly 14 years, creating a critical bottleneck for manufacturers planning to expand renewable energy capacity.

READ MORE: Nissan boss says UK is 'not a competitive place to build cars' with 'all sorts of different issues'

Sir Keir Starmer has taken steps to support the UK's automotive manufacturing sector

| PAThis lengthy wait threatens to slow both the energy transition and the shift to electric vehicle production.

With new zero emission models and gigafactories in development, the sector's demand for affordable clean energy is set to grow exponentially.

The infrastructure delays risk undermining the significant investments manufacturers have already made in renewable energy systems.

Industry leaders warn that without urgent reform to accelerate grid connections, factories will struggle to secure the green electricity supply needed to produce the electric vehicles essential for meeting Britain's net zero commitments.

LATEST DEVELOPMENTS:

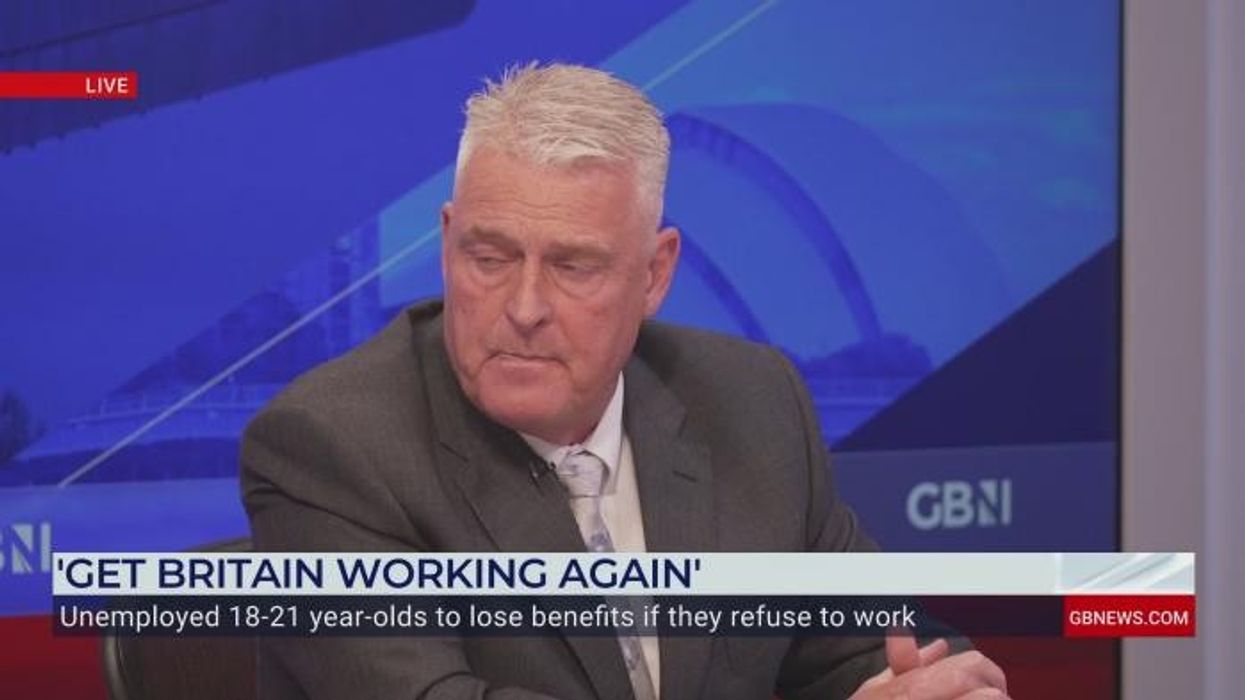

High electricity costs continue to hamper the sector's competitiveness, with UK manufacturers paying double the European average for power.

This significant cost disadvantage affects automotive businesses attempting to invest in new products, production lines and workforce development, as noted by Nissan's UK chief.

Labour Industrial Strategy has recognised the automotive industry's economic importance and proposed reforms that could reduce electricity bills by a fifth.

However, the planned relief on standing charges will apply to battery production and other energy-intensive industries, but not automotive businesses.

The UK boss of Nissan has complained about the expensive electricity prices at its Sunderland plant

| NISSANMike Hawes, SMMT Chief Executive, said: "Britain's automotive factories are integral to the country's decarbonisation ambitions, not just of road transport but the UK's wider industrial base.

"Both will require significantly more electricity from the grid, but with faster grid connections and reduced energy costs, the necessary investment will be unlocked."

Manufacturers want the proposed relief on standing charges extended to automotive businesses, arguing their trade intensity and central role in delivering net zero justify inclusion.

Hawes emphasised the urgency: "The industry cannot afford to wait, and nor can the country if our net zero ambitions are to be realised."